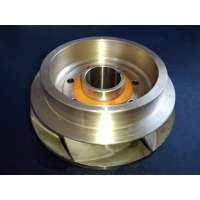

Sand Slurry Pump Impeller (DG4137)

China Dg4137 Sand Slurry Pump Part A05 Impeller, Find details about China Pump Impeller, Metal Impeller from Dg4137 Sand Slurry Pump Part A05 Impeller - Shijiazhuang Naipu Pump Co., Ltd.

Description

- Model NO.: 6/4 D-G

- Max.Capacity: >400 L/min

- Impeller Number: Single-Stage Pump

- Influent Type of Impeller: Single Suction Pump

- Pump Casing Combined: Horizontal Split Pumps

- Impeller: Closed

- Material: A05, A49, A61...

- Impeller Vane: 3-5 Vane

- Trademark: Naipu or OEM

- Specification: CE, SGS, ISO9001

- HS Code: 8413910000

- Max.Head: 30-50m

- Driving Type: Motor

- Working Pressure: Low Pressure Pump

- Position of Pump Shaft: Horizontal Pump

- Mounting Height: Suction Centrifugal

- Usage: Pump

- OEM: Accepted

- Impeller Size: 378 mm

- Transport Package: Standard Export Wooden Cases

- Origin: Shijiazhuang, China

1. Slurry pump impeller

Slurry pump impeller - high anti-abrosive can be supply with huge amount within a short period.

Naipu Impeller is one of the most important parts of slurry pump. When impeller is rotating, the slurry pump could meet the requirements of the equipment. However, it is a component, which is worn out very easily. Therefore, for long service life of the impeller, the material plays an important role here.

Naipu pump offers the two solutions for this problem. We choose the white iron, high chrome (27%) for the strong abrasive slurries, also with the sharp particles. For the corrosive slurries with blunt particles, we recommend the natural rubber.

Wear resistant cast alloys are used for slurry pump liners and impellers where conditions are not suited to rubber, such as with coarse or sharp edged particles, or on duties having high impeller peripheral velocities or high operating temperatures.

Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

2. Metal impeller material

Sand slurry pump Impeller part code: DG4137, EG6137, FG8137, FG10137, GG12137, GGH10137, HG14137...

1) Material: A05,W1, W2, NA, Cr15Mo3, Cr24, Cr26, Cr27...

2) Vanes from 3-6. It depending on the size of the particles in the slurry.

3) Impeller type including Close, Semi-open and Open type. Impellers are generally closed because of higher efficiencies and are less prone to wear in the front liner region. Open impellers are more common in smaller pumps or where particle blockage may be a problem or where the shear provided by an open impeller is an aid to pumping froth.

4) We can also produce the non-standard impellers for some special situations.

Pumping coarse coal

Pumping fibrous material

Reduced diameter impellers

Reduced eye impellers.

3. Sand pump construction drawing

4. G sand pump selection chart

5. Pump performance parameters

Model |

Flow (m3/h) |

Head (m) |

Speed (r/min) |

Efficiency (%) |

Motor (kw) |

Drive type

|

6/4 D-G |

187-36 |

7-51 |

1400-600 |

30-58 |

52-3 |

CV.CR.DC |

8/6 E-G |

576-133 |

10-48 |

1400-800 |

60-54 |

88-11 |

CV.CR.DC |

10/8 F-G |

930-216 |

11-44 |

940-500 |

65-34 |

147-22 |

CR.DC |

12/10 G-G |

1512-360 |

11-58 |

850-400 |

70-50 |

305-24 |

CR.DC |

14/12 G-G |

3168-522 |

9.5-66 |

700-300 |

68-60 |

643-29 |

CR.DC |

16/14 TU-G |

3024-900 |

14-45 |

500-300 |

70-50 |

459-78 |

CR.DC |

8/6 F-G |

648-126 |

15-77 |

1050-500 |

71-50 |

177-12 |

CR.DC |

10/8 F-G |

1091-324 |

19.2-56.5 |

800-500 |

72-60 |

205-32.4 |

CR.DC |

12/10 G-G |

2232-612 |

28-77 |

700-450 |

73-60 |

558-89 |

CR.DC |